Battery: Cell Testing

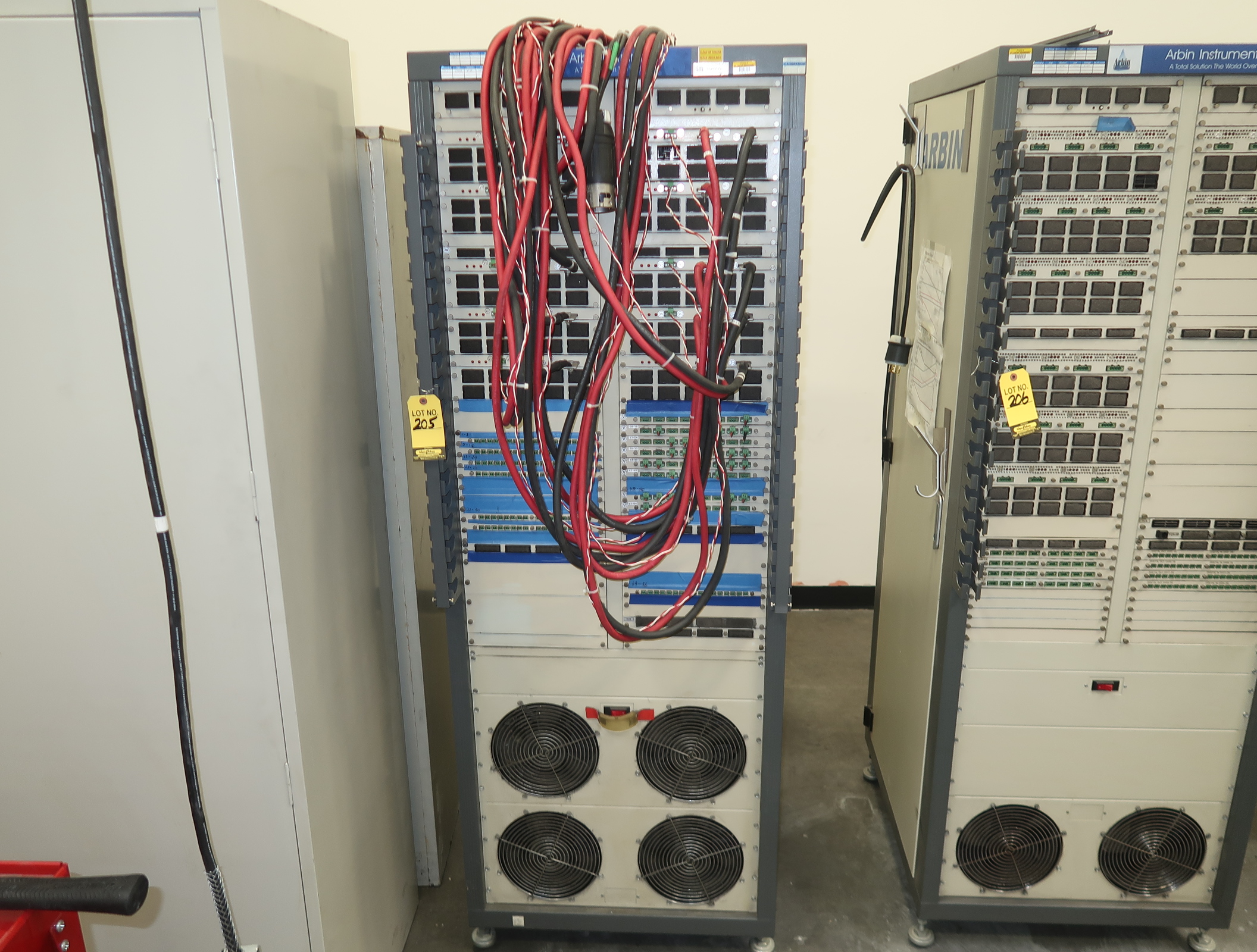

Arbin’s LBT series battery test equipment is designed for long-term life cycling as well as simulating complex real-world test profiles such as EV drive profiles, smart battery pulse charging, and other custom charge/discharge regimes. It is the go-to choice for researchers around the world.

or [Preview the Report]

Cell Voltage up to 10V

Cell Current up to 2500A

Ability to test up to 96 cells with a single chassis.

Arbin offers battery testing systems for basic charge/discharge cycling, and simulating complex real-world applications such as drive profiles, telecom pulses, or other custom profiles.

Arbin’s Laboratory Battery Testing (LBT) series commercializes technology established during a 3‐year ARPA-E project developing ultra‐high precision testing systems. This product consists of independent potentiostat/galvanostat channels for testing batteries and other energy storage devices, and is intended to provide an economical solution for applications requiring high‐precision measurements and fast data sampling. All Arbin testing systems come with a PC preloaded with our MITS Pro and Data Watcher software for creating test profiles, real‐time data monitoring, and data plotting & analysis.

Primary Applications:

- Electrochemistry, Battery & Supercapacitor Testing

- Coulombic Efficiency (HPCE) Measurements

(HPTor MSTATseries is recommended) - Life Cycle Testing

- EIS (electrochemical impedance spectroscopy)

General Specifications

Find many great new & used options and get the best deals for Arbin BT-G Battery Tester: 32 channels, 0-5 volts, +/- 5 amps at the best online prices at eBay! Free shipping for many products! The Arbin LBT21024 Battery Test System is a 0-10V, 8-channel, 100A/25A/5A/500mA battery life cycle tester with high-precision measurement and high-frequency data sampling capabilities. Arbin Instruments BT-2000 Battery Load Tester Load Board HPLA 135914 Z5 $49.99 + shipping. Elamed Easyton Intraocular Pressure Tonometer Measure Pen TVGD-02 Brand New.

Measurement Resolution: 24-bit (1 part in 16,777,216)

Measurement Precision: <25ppm or <100ppm

Control Accuracy: <0.01% or <0.02%

Minimum Step Time: 5ms

Data Logging Rate: 2000points per second, per system

Connection for PC: TCP/IP (Ethernet)

Ventilation Method: air-cooledwith variable speed fans

Key Features:

- Fully independent high precision test channels with full potentiostatic, galvanostatic control

- Allows integration with an approved EIS module for 10uHz to 2MHz measurements without changing connection.

- Each channel provides 4 or more current ranges with industry‐leading 24‐bit resolution

- Powerful embedded controllers provide fast data logging (2000 points per second, per system ) and control flexibility for the most advanced test requirements

- Any number of channels can be operated in parallel for increased current‐handling capacity

- Uses true Bipolar Linear circuitry providing cross‐zero linearity and zero switching time between charge and discharge

- Systems are air-cooled with variable speed fans so no additional facility infrastructure or regular maintenance is needed.

- Arbin’s advanced software package,MITS Pro, provides flexible scheduling, a user‐friendly interface, distributed system control, data acquisition, management, & analysis

- Software provides easy data analysis and plotting based in Data Watcher and Microsoft Excel

- A wide array of auxiliary inputs/outputs are available for additional data collection or control such as temperature monitoring, additional reference electrodes, and more

Safety:

Battery Cell Testing Equipment

- Multiple levels of fusing are provided inside the system for protection as the channel/board and power supply levels.

- Each channel module has a fully redundant microcontroller dedicated for safety monitoring.

- Arbin’s software has safety functions for entire tests, and for individual steps within a test to help the user avoid overcharging, over‐discharging, over‐heating, etc.

- Tests begin with a built‐in safety check of all control values.

Arbin Instruments provides a wide variety of auxiliary modules for expanding the capability of the main charge/discharge control circuitry. Modules can either be placed in the main chassis, or in a small external chassis. This also makes it easy to add auxiliary options to existing systems.

| Arbin offers an EIS Interface for approved 3rd party EIS modules for customers who wish to perform electrochemcial impedance spectroscopy experiments. The EIS Interface allows a single EIS module to be shared across up to 32 channels; fully maximizing the duty cycle of EIS station and Arbin tester. No change in connection is necessary. Frequency range of 10uHz to 2MHz. |

| Arbin offers Auxiliary Voltage Inputs that can be used as additional reference electrodes in a multi-electrode experiment. Data logged from auxiliary voltage inputs can be flexibly assigned by the user to one, many, or all of the main charge/discharge channels. Measurements can be used to control the test, act as safety limits, or simply record data. |

| Temperature Measurement Inputs are offered for Type-T or K Thermocouple, or 10kohm or PT100 Thermistor sensors. Temperature data logged from these inputs can be flexibly assigned by the user to one, many, or all of the main charge/discharge channels. Temperature can be used to control the test, act as safety limits, or simply record temperature measurements. |

Arbin’s Cell-Isolating Thermal Safety Chamber (MZTC)is a battery test chamber with 8 independent temperature chambers in 1. Insulation and protection between each chamber provides greater temperature control and a safe testing environment by isolating each cell or set of cells, as well as making connections easy. |

Arbin EV Battery Pack Tester with Chamber This module allow’s the Arbin tester to interfacewith approved 3rd party temperature/environmental chambers from other manufacturers. The Arbin software can turn the chamber on/off and adjust temperature during testing. Temperature setpoints from the chamber controller are automatically logged in the data and independent temperature measurements are available using thermocouple or thermistor inputs. |

| Digital and Analog Input/Output channels are offered to interact with external hardware devices. — The Digital I/O will send and receive a simple on/off, high/low relay signal. It can activate a BMS, receive a confirmation signal, and many other options. — The Analog I/O will control any device that operates in a 0(2)-10V signal such as pumps, valves, etc. |

| Arbin’s Auto-Calibration module allows channels to be calibrated automatically with connected to an appropriate source meter. While the calibration interface is built into the software for all systems, this module removes the need for human involvement in the process and is recommended for systems with channel quantities greater than 32. |

| The Uninterrupted Power Supply (UPS) option will provide backup power to the PC with your Arbin system. It allows the test to automatically pause and wait for power to be restored to the tester and will automatically and safely resume testing after brief outages. Otherwise, the software and PC will safely be shut down. |

| A variety of Battery Holders and Racksare available for coincells, cylindricalcells, pouch/flat cells, and more. These individual holders are available for currents up to 300A. The wheeled battery racks make it easy to organize large quantities of cells with removable trays and cable organization. [Learn More] |

| The Redundant Safety Monitoring System (RSMS) can be placed in series with any battery tester including those from USA, Europe, and Asia. The RSMS allows users to set a limit for Voltage, Current, Power, and Temperature that will automatically disconnect the battery or device under test is a safety limit is reached. Many manufacture’s claim to have comprehensive safety features, but the RSMS guarantees and extra layer of protection to help prevent failure events. [Learn More] |

| Model | Voltage Range | Current Ranges | Model | Voltage Range | Current Ranges | |

| LBT ±5V – 200mA | (-5) to 5V | 200mA/10mA/1mA/100μA | LBT 5V – 30A | 0 to 5V | 30A/5A/500mA/20mA | |

| LBT ±5V – 1A | (-5) to 5V | 1A/50mA/2mA/100μA | LBT 5V – 60A | 0 to 5V | 60A/5A/500mA/20mA | |

| LBT ±5V – 5A | (-5) to 5V | 5A/500mA/20mA/1mA | LBT 5V – 100A | 0 to 5V | 100A/10A/1A/100mA | |

| LBT ±5V – 10A | (-5) to 5V | 10A/500mA/20mA/1mA | LBT 5V – 250A | 0 to 5V | 250A/50A/5A/500mA | |

| LBT 5V – 5A | 0 to 5V | 5A/500mA/20mA/1mA | LBT 5V – 300A | 0 to 5V | 300A/50A/5A/500mA | |

| LBT 5V – 10A | 0 to 5V | 10A/500mA/20mA/1mA | LBT 5V – 500A | 0 to 5V | 500A/50A/5A/500mA | |

| HPT-100mA | 0 to 5V | 100mA/10mA/1mA/100uA | ||||

| HPT-1A | 0 to 5V | 1A/100mA/10mA/1mA | ||||

| HPT-5A | 0 to 5V | 5A/1A/100mA/10mA | ||||

| Custom LBT models for cell testing are available up to 10V and up to 2500A. | ||||||

Importance of Precision

This plot illustrates the difference between an Arbin battery tester and another leading manufacturer. The two distinct dips in the plot may have been missed using inferior test equipment. While many companies try to sell the same antiquated equipment for over a decade, Arbin has been hard at work improving our designs to meet future industry demands. We learned a lot during our three year ARPA-E project to develop high-current high-precision testers, and have implemented this new technology in our MSTAT, LBTand HPTtest equipment series. The HPT and MSTATsystems represent our premium product, but LBTis superior to other standard testers on the market.

What Affects Tester Precision | Arbin Tester Improvements |

Measurement precision is more critical for long‐term battery testing and long‐term battery projections than control accuracy alone. Most other battery testing systems do not correctly specify their precision and/or have relatively poor precision, which hinder the conclusions drawn from results data. Important trends and electrochemical indicators may remain unnoticed; lost in the measurement noise as illustrated above.

Our hope is that these higher degrees of measurement precision will lead to new discoveries and characterization metrics across the energy storage industry for all organizations, not only those looking at coulombic efficiency as a key indicator.

How to Evaluate Battery Test Equipment

Batteries are a critical component of many products, and energy storage plays a very active role in our lives even outside of the research/industry setting. Therefore, selecting the right battery test equipment is an important decision for companies and the individual researchers who are responsible for producing results, whether they are starting small, or at massive scale.

Autozone Battery Tester

The expert engineers at Arbin have been advancing the benchmark of “state-of-the-art” battery test equipment for over 27 years. We are defined by innovation, from being the first to apply multiple current ranges on a single test channel to more recently being the only company to offer true high-precision testing for high current applications, and supporting “Turbo Mode” with smart battery modules. We continue to learn from our industry partners and work with them on key technology breakthroughs.

Arbin Battery Tester Price

The following report shares some of this knowledge using plain terminology and illustrations. Here are five key topics to consider when choosing battery test equipment:

1. Hardware – Specifications & Quality of Materials [Preview Report]

2. Software – Usability and Features

3. Data – Logging, Management, and Analysis

4. Options – Auxiliary Features and Accessories

Used Arbin Battery Tester For Sale

5. Support – Product Safety and Support